Due to water pressure, clogging, and corrosion, sewer lines can be damaged after some time. As they are buried in the ground, they can also be damaged by outside forces. The location makes it difficult to determine whether it needs any repairs or if it has any damage.

Damages in the pipe and sewer lines must be addressed before they get worse, just like with any other property issue. To check your pipelines, you should call a plumbing company.

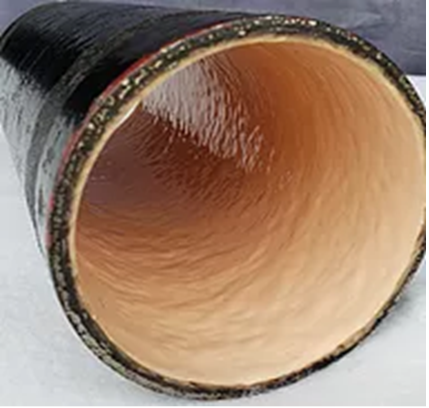

If a sewer pipeline is unnoticed, you can end up with a deteriorated home. A process called pipe lining can be used to quickly repair damaged pipes. Corrosion, leaks, and cracked pipes can be restored with this process.

As a result, you do not need to dig up your garden, lawn, or driveway to inspect and repair your pipes. Therefore, whenever you need to have your pipes or sewer lines checked, you can save time and effort.

How Long Can Pipe Lining Last

The lining of a pipe does not last forever, but it can last for quite some time. Pipelining is intended to double the lifespan of the pipes you already own. The actual pipe lining may exceed the 50-year insurance period provided by the pipe lining. It’s possible to find some with a 100-year lifespan. It’s more than a lifetime!

Pipe lined sewers can, however, be affected by some aspects. Several forces can damage pipes again, such as tree roots and earthquakes. Moreover, material also plays a role. Pipe linings come in four different types today. Each type is installed differently and has a different life expectancy.

Pull-In Place

Pipes that are pulled in place can last up to 40 years. Usually, this method is used to repair damages like wide cracks and gaps. Named after the process of pulling the epoxy-saturated liner.

This method requires two points of entry. To install the lining into the first pipe, they used steam to drill into it. The liner can also be pulled through the other entry point. After it’s blown up, they let it dry.

Internal Pipe Coating

The next step is internal coating, which can last more or less 50 years. The method should be used for sections of pipes with holes, corrosion, cracks, and root damage. The damaged line is repaired through the drain by pumping epoxy through bendable metal tubes and applying epoxy. The epoxy is then spread throughout the pipe’s interior using a rotating brush.

Cured-In Place

The pipe lining can also last for 50 years using this method, but it works better on larger pipes. Cleaning and drying of the pipe are the first steps in the process. Once again, lining is applied to damaged sections, which is then fastened into place with UV light, steam, or hot water.

Pipe Bursting

Pipe bursting is the most durable of all the pipe lining methods. Whether you believe it or not, it can last for 100 years, but it can be a noisy process. Due to the need for two access points, pipe bursting begins by digging on either end of the damaged pipe. Bursting heads are inserted in the entry point. Hydraulic power is used to push it through the line. Through the existing pipe, a new one is pulled through from the bursting head. In the process of installing the new pipe, the damaged older one is broken off and removed through the second entry point.

Conclusion

The type of pipe lining method to use depends on the type and extent of the damage. Professionals need to perform these processes because they possess the knowledge, equipment, and license needed. It is obvious that you cannot DIY this project with only home piping materials and basic plumbing skills. There’s an incredibly innovative way to repair pipes that creates as little damage to the surrounding area as possible.

For this method to be effective, you must watch out for any signs of pipe damage. The only way to fix dilapidated pipes is to replace them completely. In addition to being innovative, pipe lining is also cost-effective and reliable since it can also last for up to 100 years.