There are many factors that can lead to the gradual deterioration of sewer pipes, including heat, corrosion, erosion, abrasion and root damage. Digging up the ground to reach the underground piping system is the traditional method of solving these problems. This technique can, however, create an unsightly construction zone and cause extensive damage to property.

There are many factors that can lead to the gradual deterioration of sewer pipes, including heat, corrosion, erosion, abrasion and root damage. Digging up the ground to reach the underground piping system is the traditional method of solving these problems. This technique can, however, create an unsightly construction zone and cause extensive damage to property.

Sewer pipe coating is considered a more reliable and less intrusive alternative to traditional repair methods by many companies. Trenchless Pipe Repair provides superior sewer pipe coating services in Minnesota and beyond.

How Does Sewer Pipe Coating Work? What Does It Do?

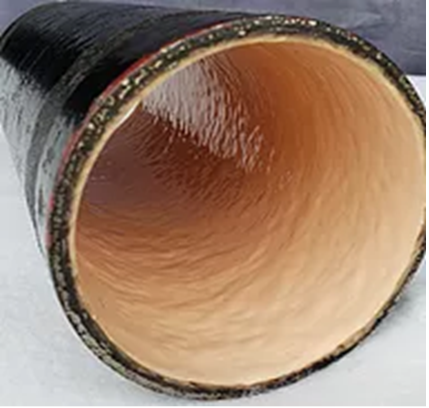

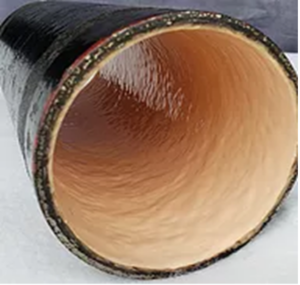

With Quik-Coat pipe lining coating, sewer pipes can be restored to like-new condition in a quick, safe, and environmentally friendly manner. To reach underground pipes, the technique entails inserting a specially designed brush or spray head attached to a hose and cable into the pipe instead of digging trenches. The hose is flexible enough to bend as it travels through the piping system. Brushes or spray heads apply resin that hardens to create a protective “pipe within a pipe.”

What problems can pipe coating solve?

For many common piping problems, pipe coating provides a long-term solution. Cracks can be sealed, leaks prevented and structural integrity improved. In addition to preventing future problems, it can extend the lifespan of the pipes and prevent expensive repairs.

How We Coat Sewer Pipes

Our trenchless technology pipe lining and relining engineers arrive at your site to perform camera inspections and diagnostics. Additionally, we will also let you know which option will work best for your specific situation. A state-of-the-art trenchless technology is used during this process. By sliding through and maneuvering around 90 degree turns and offsets, it seals the pipe internally.

Several things can cause offsets: small leaks under the lines causing ground to wash out shifting foundations, tree roots pushing on the pipe or, in the worst case, root infiltration.

With a liner, you will never have to worry about it collapsing or stretching into the city sewer mainline. Additionally, no expensive reinstatement cutters are required! Your landscape or structure will benefit from saving money, time, and the environment! Providing the most cost-effective solution for sewer pipe repair is what we do best!

Coating pipes has many benefits

When compared to traditional pipe coating processes, pipe coating offers the following advantages:

- Corrosion protection: Polyurea prevents rust from forming on metal surfaces

- Chemical resistant: Ensures that harsh chemicals don’t damage it

- Erosion prevention: Reduces the risk of piping material corroding

- Improves flow efficiency: Less clogging of drains and pipes as a result of water flowing freely

- Abrasion resistant: The coating won’t wear off or rub off over time

- Thermal resistant: It can withstand temperatures of up to 120 degrees Fahrenheit

- Seals separated joints and cracks: Improves pipe structural integrity

- Ecologically friendly: Trenchless construction won’t destroy the landscape

- Moisture insensitivity: The coating will not be affected by groundwater

- 10-second set time: Polyurea cures in a fraction of the time of most epoxy coatings

- Customizable coat application: The product can be applied in accordance with the application requirements

- Withholds up to 200 PSI: Resists high pressures of water without damaging the coating

- Works on any size 3-inch to 24-inch, and 300-feet in length: Adaptable to different pipe sizes and lengths

- Safe for drinkable water and environment (NSF 14 & 61 approved): The pipe coating process poses no health or environmental hazards